Piezo Ultrasonic Sensor Applications

Piezoelectric sensors convert a physical, acceleration, pressure, or other input to an electrical signal that serves as an input to a data processing system. This sensor signal often results in a response from the system. One example of such a piezo sensor is an accelerometer. Accelerometer sensors often measure vibration or acceleration of various devices, such as motors, pumps, etc. A piezoelectric sensor of this type is often used to measure vibration of motor bearings, or other device, to determine the wear on the bearing so that maintenance can be performed before there is a catastrophic bearing failure.

An automotive knock sensor is another example of an accelerometer sensor that is used to measure the engine vibration to adjust the fuel / air ratio to reduce engine vibration and “engine pinging”, thereby resulting in improved engine performance.

Using Ultrasonic Sensors With Liquids

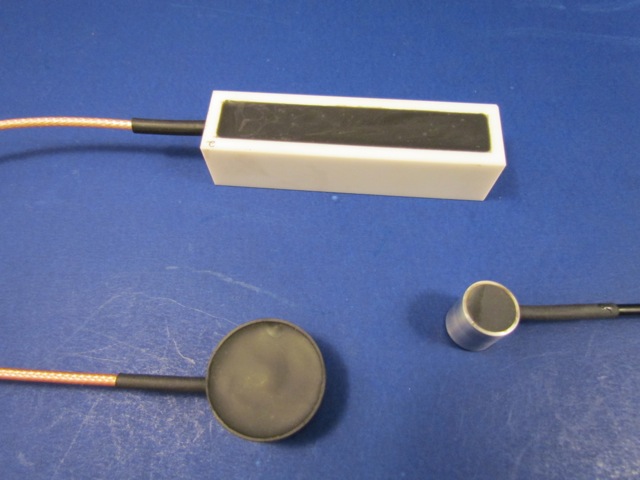

Another group of piezo sensors operate on the principle of measuring distance in a fluid, primarily through the use of transit time measurements and a corresponding data processing system. This system can yield a preprogrammed response that will control some aspect of the process by keeping the operation within desired operating parameters. An example of this sensor system would be the throttling of a valve in the following applications for piezo flow and level sensors.

Piezoelectric liquid flow sensors are often used in pairs and operate by utilizing the difference in transit time for a signal traveling in the direction of fluid flow compared to the transit time for a signal traveling against the fluid flow. This transit time difference is related to the velocity of the flow in the vessel, and therefore the flow or volume/second can be determined with the configuration of the vessel and the characteristics of the liquid.

Level Sensors

Piezo level sensors can determine the amount of material remaining in a bin, and can be used to control the bin contents. These sensors operate by intermittently shooting a sound beam at the surface level of the material in the bin, and receiving back the reflection of that sound beam as it reflects off of the surface. Knowing the speed of the sound wave in air, and the transit time for this sound wave to travel to the material surface and back to the sensor, one can determine the distance of the material surface from the sensor. This information along with information of the geometry of the vessel and the position of the sensor and the characteristics of the material in the bin allows for accurate calculation of the amount of material in the bin. An additional advantage of a piezo sensor in this application is that the piezo sensor beam is not affected by dust in the bin that may result during the material charging operation.