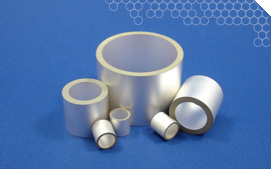

Piezo Tube (Cylinder)

- selection of standard dimensions

- highest purity lead zirconate titanate ceramics

- custom compositions / dimensions / electrode placement

- high volume production capability

- competitive pricing

- fast delivery

Typical Applications of Piezo Tubes

- fiber optics

- scanning electron microscopes

Custom Designed and Engineered Piezoelectric Tubes (Cylinder)

To meet your unique specifications, APC International can manufacture piezo tubes (cylinders) in a wide range of sizes and thicknesses and out of materials other than our standard cylinder materials. To discuss your requirements, contact an APCI representative with your drawing or sketch including: tolerance values, material, and electrode pattern.

Standard Piezo Tubes (Piezoeletric Cylinders)

The materials used in APC's standard piezo cylinders are specially formulated for cylinders. APC's Type I and Type II materials are high density, fine grain, PZT ceramics that exhibit a high dielectric constant, high electromechanical coupling factor, high charge sensitivity, and a high Curie point (See Material Specifications). Clean responses make these ceramic materials ideal for various low-power and high-power piezo devices:

- ultrasonic or doppler flow meters

- gas flow sensors

- other flow or level sensors

- sensors for ultrasonic NDT / NDE applications

- sensors for inspecting construction materials, welds, etc. in automotive, structural, and other applications

- various high-power applications

Electrodes are located on the inside surface (ID) and outside surface (OD) of the cylinder. The piezo cylinders (tubes) are poled through the wall thickness with the ID being positive. Please inquire about other poling options.

| APCI Catalog No. |

Material | Dimensions(mm) | Capacitance at 1kHz (pF) |

Resonance Freq. (kHz) | ||||

| OD | ID | Length | Length | Thickness | Radial | |||

| 42-1094 | Type II | 3.0 ± 0.15 | 2.0 ± 0.15 | 5.0 ± 0.15 | 1,200 | 260 | 4,000 | 420 |

| 42-1096 | Type II | 5.0 ± 0.15 | 4.0 ± 0.15 | 10.0 ± 0.15 | 4,500 | 130 | 4,000 | 233 |

| 42-1001 | Type II | 6.35 ± 0.15 | 4.9 ± 0.15 | 6.35 ± 0.15 | 2,500 | 260 | 2,760 | 160 |

| 42-1007 | Type II | 10.0 ± 0.25 | 8.0 ± 0.25 | 10.0 ± 0.15 | 4,500 | 165 | 2,000 | 100 |

| 42-1012 | Type II | 15.5 ± 0.25 | 11.2 ± 0.25 | 18.0 ± 0.15 | 5,500 | 92 | 930 | 67 |

| 42-1022 | Type II | 19.0 ± 0.25 | 16.0 ± 0.25 | 20.0 ± 0.15 | 11,600 | 83 | 1,330 | 51 |

| 42-1032 | Type II | 22.0 ± 0.25 | 16.0 ± 0.25 | 20.0 ± 0.15 | 6,300 | 82 | 670 | 47 |

| 42-1036 | Type II | 26.0 ± 0.25 | 22.0 ± 0.25 | 20.0 ± 0.15 | 12,000 | 83 | 1,000 | 38 |

| 42-1042 | Type II | 30.0 ± 0.25 | 26.0 ± 0.25 | 20.0 ± 0.15 | 14,000 | 83 | 1,000 | 32 |

| 42-1052 | Type II | 38.0 ± 0.35 | 34.0 ± 0.35 | 25.0 ± 0.15 | 22,500 | 66 | 1,000 | 25 |

| 42-1062 | Type II | 44.0 ± 0.35 | 38.0 ± 0.35 | 30.0 ± 0.15 | 20,500 | 55 | 670 | 22 |

| 42-1072 | Type II | 50.0 ±0.35 | 46.0 ±0.35 | 30.0 ± 0.15 | 36,000 | 55 | 1,000 | 19 |

| 42-1081 | Type II | 68.0 ± 0.35 | 60.0 ± 0.35 | 25.0 ± 0.15 | 20,000 | 66 | 500 | 14 |

| 42-1092 | Type II | 85.0 ± 0.35 | 77.0 ± 0.35 | 30.0 ± 0.15 | 30,400 | 55 | 500 | 11 |

| 42-2094 | Type I | 3.0 ± 0.15 | 2.0 ± 0.15 | 5.0 ± 0.15 | 1,000 | 320 | 4,150 | 480 |

| 42-2096 | Type I | 5.0 ± 0.15 | 4.0 ± 0.15 | 10.0 ± 0.15 | 3,500 | 160 | 4,150 | 256 |

| 42-2001 | Type I | 6.35 ± 0.15 | 4.9 ± 0.15 | 6.35 ± 0.15 | 1,900 | 283 | 3,000 | 176 |

| 42-2007 | Type I | 10.0 ± 0.25 | 8.0 ± 0.25 | 10.0 ± 0.15 | 3,500 | 180 | 2,180 | 110 |

| 42-2011 | Type I | 15.5 ± 0.25 | 11.2 ± 0.25 | 18.0 ± 0.15 | 4,300 | 100 | 980 | 74 |

| 42-2021 | Type I | 19.0 ± 0.25 | 16.0 ± 0.25 | 20.0 ± 0.15 | 9,100 | 90 | 1,400 | 57 |

| 42-2031 | Type I | 22.0 ± 0.25 | 16.0 ± 0.25 | 20.0 ± 0.15 | 4,900 | 85 | 700 | 52 |

| 42-2035 | Type I | 26.0 ± 0.25 | 22.0 ± 0.25 | 20.0 ± 0.15 | 9,300 | 85 | 1,040 | 41 |

| 42-2041 | Type I | 30.0 ± 0.25 | 26.0 ± 0.25 | 20.0 ± 0.15 | 10,900 | 85 | 1,040 | 35 |

| 42-2052 | Type I | 38.0 ± 0.35 | 34.0 ± 0.35 | 25.0 ± 0.15 | 17,500 | 68 | 1,040 | 28 |

| 42-2072 | Type I | 50.0 ±0.35 | 46.0 ±0.35 | 30.0 ± 0.15 | 28,000 | 57 | 1,040 | 21 |