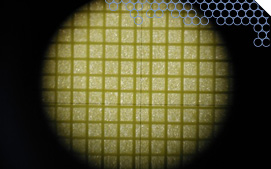

Dice & Fill Composite

The dice and fill method is the industry standard for composites with frequencies over 1 MHz. These composites are made by dicing a piezoceramic plate and filling the resulting trenches with an interstitial material such as epoxy or polymer. The distance between the pixels or rods is minimized to avoid lateral modes or other undesirable interference. The outcome is a regular pixel distribution required for phased array ultrasound transducers.

Typical Applications

- Medical Ultrasound

- NDT Phased Array Transducers

1-3 Dice & Fill Composite Specifications

- Frequency Tolerance ±10% standard, ±5% available

- Available in PZT Navy type I, II and type VI

- Custom sizes and shapes available

- Various epoxy and polyurethane interstitial materials available

- Operational temperatures up to 130C

- Electrode Material:

- Copper-Tin for all Frequencies less than 5MHz

- Silver-Gold electrodes for all frequencies above 5MHz or when requested

- Mechanical tolerances:

- For dimensions < 6mm±0.1mm

- For dimensions < 30mm±0.2mm

- For dimensions ≥ 30mm±0.3mm

Typical Pixel/Fill Combinations Available (60mm x 60 mm plates):

| Pixel Size/Fill | Navy Type II Frequency* |

| 400µm/65% | 1 to 2 MHz |

| 200µm/45% | 1.5 to 5 MHz |

| 200µm/65% | 1.5 to 5 MHz |

| 100µm/45% | 3.5 to 10 MHz |

| 100µm/65% | 3.5 to 10 MHz |

When Ordering or Requesting a Quote, specify the following characteristics

- Composite Type

- Material

- Shape

- Frequency

- Fill%

- Electrode Type