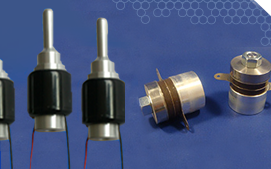

Ultrasonic Power Transducers

- high efficiency

- large amplitude

- low heat

- stable output unaffected by variations in load

- competitive pricing

- fast delivery

Typical Applications of Piezo Ultrasonic Transducers

Piezo ultrasonic transducers are used in a wide range of applications. In both commercial and industrial environments, these devices allow ultrasonic cleaning apparatus to work effectively — even in the most demanding and delicate of activities, such as in ultrasonic jewelry cleaning.

In healthcare applications, piezo ultrasonic transducers provide capabilities such as the ultrasonic breaking up of kidney stones and the removal of dental plaque. In addition, they're used to conduct precise measurements to identify flaws and other anomalies detected between the transmitters and receivers of ultrasonic waves.

Sound Transducers

Unlike other forms of energy, like radiation — which can be harmful to humans and other life forms — ultrasound is merely a form of sound that exceeds the upper audible limits of the average adult. Beginning at 20 kHz and upwards, ultrasonic transducers can make use of these physically shorter wavelengths. As a result, these types of transducers are ideal for use in nondestructive test situations, as well as for the precise measurement of various materials and physical matter, including conducting ultrasounds on human patients.

Frequency Response Function

The high mechanical quality of APC's piezo transducers ensures that these sandwich-type ultrasonic transducers offer high electro-acoustical efficiency and low heat generation. The mechanical connection of the piezoelectric elements assures a large amplitude output. APC's standard ultrasonic cleaning transducers are available in four frequencies: 28 kHz, 40 kHz, 80 kHz, or 120 kHz. APC also offers a 50 kHz power transducer that can be used in a variety of applications, including as a fabric cleaner, nebulizer, atomizer, for ultrasonic mixing, or for cell disruption.

Standard Ultrasonic Cleaning Transducers

| APCI Catalog No. |

Drive Frequency |

Mechanical Quality (Qm) |

Coupling (Kp) (%) |

Capacitance (1 kHz) (nf) |

Impedance (ohm) |

Motion Admittance (mν) |

Allowable Vibration (cm/sec) |

Power (watts) |

|

| 90-4040 | 28 kHz | 800 | ≥55 | 3.8 | ≤50 | 60 | ≤25 | 50 | Spec Sheet |

| 90-4050 | 40 kHz | 800 | ≥55 | 3.8 | ≤50 | 65 | ≤50 | 50 | Spec Sheet |

| 90-4060 | 80 kHz | ≥1000 | ≥55 | 3.7 | ≤50 | 80 | Spec Sheet | ||

| 90-4070 | 120 kHz | ≥1000 | ≥55 | 3.7 | ≤50 | 80 | Spec Sheet | ||

| Custom | Values to be Determined by Customer and APC International | ||||||||

Ultrasonic Transducer Generator Specifications (Cat. # 90-4200 & 90-4210)

Download the Ultrasonic Transducer Generator Spec Sheet.

Standard Ultrasonic Power Transducer

| APCI Catalog No. |

Part # | Resonant Frequency |

Resonant |

Capacitance |

Bandwidth | Insulation Resistance |

|

| 90-5000 | APC-4SS-1550 | 50 ±2 kHz | 60Ω (MAX) | 2750±20%pF | Δf ≥ 1.0 kHz | R ≥ 500M Ω 2500VDC | Spec Sheet |

| 90-5010 | APC-4SS-1500 with PCB | Catalog #90-5000 with power supply | Spec Sheet | ||||

| Custom | Values to be Determined by Customer and APC International | ||||||

How To Make Ultrasonic Transducers for Ultrasonic Cleaning: Composite Transducers

As is true in many other applications for piezo¬electric materials, an assembly of multiple ceramic elements offers considerable performance and production advantages in ultrasonic cleaning transducers, relative to a single ceramic element. In order to provide the most efficient operation, simplify manufacturing, and reduce costs, more complex transducers intended for ultrasonic power applications usually are a composite of a piezoelectric ceramic center (multiple thin rings or disks of ceramic, for example), encompassed by metallic end or top and bottom parts. Under no liquid load, the mechanical quality factor, Qm , for a well-designed composite transducer will be greater than the correspond¬ing value for an equivalent single piece ceramic transducer, and efficient heat conduction by the metallic portions will ensure a lower operating temperature in the ceramic portion of the transducer. The coupling factor, k, will approach that for a single-piece ceramic transducer.

Pressure Transducers

The metallic portions of a composite transducer should have the same acoustic properties and cross-sectional area as the ceramic portion. Both metallic parts can be constructed from the same material or combination of materials, or the two parts can be made from materials with divergent properties. Potential construction materials include steel, aluminum, titanium, magnesium, bronze, and brass. Often, only one of the metallic parts is intended for high intensity output.

For maximum energy transfer from the transducer to the solvent in the ultrasonic cleaning tank, a composite ultrasonic transducer usually is a half-wavelength transducer with a resonance frequency of 20 kHz or 40 kHz. The electroacoustic efficiency of a composite ultrasonic transducer has an inverse relationship with the electromechanical coupling factor and the various quality factors of the components.

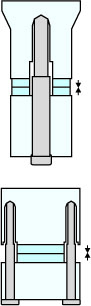

Pre-Stressed Composite Ultrasonic Transducers

Seldom will the ceramic component of a composite transducer have adequate tensile strength to withstand the high mechanical stress associated with the power demands for ultrasonic cleaning applications. The tensile strength of the ceramic elements can be supplemented by mechanically pre-stressing the elements along the direction of polarization. Pre-stress is introduced by incorporating a single, large, central bolt or several smaller, peripherally arranged bolts into the design of the transducer. The single central bolt design offers slightly higher efficiency than the multiple peripheral bolt design, but manufacturing costs can be higher, assembly can be more difficult and, physically, the transducer will be significantly longer.

How Does An Ultrasonic Transducer Work

For the conditions under which ultrasonic cleaning devices are operated, pre-stress of less than approximately 30 MPa usually is sufficient to protect the ceramic components of the transducer. On the other hand, if the prestress is too low, excessive mechanical losses at the ceramic / metallic interfaces can reduce efficiency. Pre-stress can be estimated by using a torque wrench, calibrated against charge, to tighten the bolts. This measuring method is simple, but it is not the most accurate, and consequently it is recommended primarily for production-run transducers for which the variations among corresponding components are, hopefully, minimal. The more accurate way of measuring pre-stress is to measure the charge generated in the ceramic elements under short circuit conditions. A capacitor connected to the transducer’s electrical terminals and to a direct current voltmeter facilitates measurement of the charge as each bolt is tightened.

Ultrasonic Transducers And Water

In ultrasonic cleaning applications, effects of the dimensions and configuration of the water tank, the water load, and the thickness of the bonding layer affixing the transducer to the water tank combine to slightly reduce the frequency of the transducer, and give rise to several additional resonances. Despite these negative factors, however, a well-designed transducer, incorporated in a well-designed circuit, will operate near its resonance frequency.

Cavitation

Cavitation occurs when the vibration of a transducer surface interfacing with a liquid (usually water, but possibly a water / organic solvent mixture in an ultrasonic cleaning application) is sufficient to create a partial vacuum that exceeds the vapor pressure of the liquid, and bubbles form at the vibrating surface. Cavitation is a desirable feature in ultrasonic cleaning or liquid vaporizing applications, but obviously must be avoided in signal transmission applications. At atmospheric pressure, and with water alone as the interfacing liquid, the threshold forcavitation, pC0 (bar), is:

Equation 5.9

pC0=(0.00025ƒ)2 + (0.045ƒ-1)

For frequencies from kilohertz to several hundred kilohertz (2). If the transducer is submerged, and the vibrating surface is several meters or more below the atmosphere / liquid interface, the threshold for cavitation increases to:

Equation 5.10

pCh=pC0 + 0.10h

where

pCh= threshold for cavitation in atmospheres at depth h in meters (bar)

pC0= threshold for cavitation at zero depth (bar)

Cavitation (J) can be initiated when the acoustic intensity at the vibrating surface, in W/cm2, is:

Equation 5.11

J=0.15(pC0 + 0.10h)2

The acoustic intensity at the vibrating surface can be determined from: (acoustic output power of transducer) (surface area of transducer). In application, however, because the threshold for cavitation is affected by the characteristics of the transducer (signal frequency, acoustic pulse length, acoustic uniformity / non-uniformity of the vibrating face) and by various conditions (depth of submersion, temperature, dissolved air content of the liquid), cavitation may not be initiated until the acoustic intensity is significantly higher, e.g., between 0.3 (PC0 +0.10h)2 and 0.4 (PC0 + 0.10h)2.

For more information on industrial ultrasonic transducers, fill out our contact form or call us at (570)726-6961 to learn more information.