Piezo Materials and Ultrasound In The Fight Against Coronavirus

As we have discussed many times in the past, piezo ceramics are everywhere. From your BBQ grill to your smoke detector, your vehicle, and more. In the following article we present several uses of piezo materials in medical applications critical to the COVID-19 pandemic. The views discussed below are from a piezo manufacturers’ perspective and not from the viewpoint of medical professionals.

As our team began to internally discuss the role piezo materials are playing in the fight against COVID-19, it became immediately clear that their applications run deep into the medical supply chain. From ultrasonic welding during the manufacture of disposable and reusable components, to housings, packaging, and active components in the devices themselves, it’s important to understand the direct and indirect impact piezo materials have on today’s public health, safety and medical industries.

In an effort to share some of the most critical applications piezo materials are playing in this fight, below is a list of industries and applications where piezo materials and components have directly impacted today’s medical strategies:

Ultrasonic Welding of Plastic and Plasticized Fabrics:

Personal Protective Equipment (PPE):

Unbeknownst to many, most commercial N95 facemasks, surgical masks, and gowns are manufactured using polypropylene type closed weave fabrics. These fabric layers are “stitched” together by applying high energy ultrasound in a typical stitch pattern. This energy generates heat and motion, thereby bonding the layers without penetrating them. As China struggled with the virus initially, manufacturers of masks and surgical fabrics had to rely on US supplies for the piezo rings required to ramp up mask and PPE production both nationally and internationally. With most states finally re-opening businesses, the use of PPE in everyday life is an unfortunate reality where social distancing is not practical. This reality reinforces the importance placed on piezo materials during this pandemic. Next time you wear a disposable surgical mask, shield, or N95, remember that was made possible by piezo materials.

Medical Device and Ventilator Manufacturing:

Along the same lines of ultrasonic welding and bonding, high power piezo ceramics are also used to ultrasonically weld plastic materials for devices, device housings, filter housings, disposable tubes and plastic fittings, etc. Housings and fittings such as these are used in ventilators and other medical equipment used to treat the most critically ill patients.

Sterilization:

Sanitizing of Medical Devices and Spaces:

Changing gears slightly brings us to some active components used in the medical industry. Nebulization of sterilizing fluids such as isopropyl alcohol or hydrogen peroxide gives medical professionals a way to sterilize instruments without the (typically necessary) high temperatures of an autoclave, and spaces without exposing medical personnel. Both traditional nebulizing crystals (which rely on high focused energy for atomization of fluid) and piezo driven micro-mesh technologies (which relies on a flexible oscillating diaphragm to pump liquid through micromachined holes for atomization of fluid) have been, and are being, used in this application.

Ultrasonic Flow Monitoring and Flow Control:

Ventilator Testing:

Ultrasonic flow measurement is routinely used to determine the operating status of medical ventilators. By measuring volume output and pressure output, the ventilator can be cleared for use or adjusted to meet manufacturer specifications. Tools like these are necessary to keep medical ventilators operating properly and ready for patients in the ICU.

Pharmaceutical Manufacturing and Delivery:

Cleanliness of tubes and devices is of critical importance when delivering pharmaceuticals, whether directly to patients, or in the manufacturing process of the pharmaceuticals. Ultrasonic flow monitoring gives users the ability to clamp flowmeters around the outside of a tube, rather than have to splice into the tube to obtain measurement. This retains the cleanliness and sterilization of the inside of the tube, which is crucial.

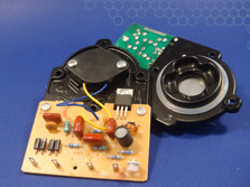

Active Piezo Based Medical Devices:

Medical Nebulizers:

Nebulizers for inhalation of medicine, typically of the micromesh variety, are used in the fight against COVID-19. The performance of the micromesh nebulizer is designed to atomize medication to very specific, critical droplet sizes. This ensures maximum retention deep in the lungs where the medications can be most effective. Other technologies for atomization of medication produce broad droplet size ranges reducing the total volume of medication retained in the lungs.

Ventilators with Nebulizer Assistance:

Utilizing several of the technologies listed above (plastic welded tubes and adapters, plastic welded housings, micromesh nebulizers, etc.) ventilators can be adapted to help deliver atomized medications deep into the lungs of patients who cannot sufficiently breath on their own as a result of COVID-19. Medical professionals can introduce the atomized medication into the ventilator tubing allowing the ventilator to distribute the medication into the lungs where it is most necessary.

Imaging Ultrasound:

When talking about piezo materials in medical applications, imaging ultrasound almost always comes to mind first. Imaging ultrasound is a time tested tool in the toolbox for medical professionals. From evaluating individual organs to potentially identifying the presence of pneumonia from the bedside, imaging ultrasound is widely available and non-invasive.

As you can see, piezo materials play a major role in the fight against the pandemic. From PPE to measurement, active devices to tubes and adapters and housings, the list above just scratches the surface of applications and devices used in the medical industry today. There are countless other applications for piezo materials in the medical supply chain, piezo based devices, and piezo driven applications relied on by medical professionals on and off the “battlefield.”

As a supplier to the medical industry serving many of the categories listed above, as well as a member the defense industrial base and US Critical Infrastructure, APC International has been a dedicated partner, following all CDC and Health Department recommendations to provide an uninterrupted flow of goods and services to our customers throughout the COVID-19 pandemic. Please contact APC International to discuss your upcoming piezo ceramic requirements.

No Comments